It won’t be a surprise to hear that one of the things we hate the most is excess packaging that ends up in the landfill (and plastic is the worst)! At Elle Crée, we work really hard at packaging our kits in a responsible way. We’re proud of our sustainable packaging and think it helps to set our kits apart from the competition.

So, how and where does our packaging get made?

Spoiler alert: It’s all produced within a 25 mile radius of our workshop!

Packaging design can be tricky, but Rachel’s background in graphic design and her existing relationships with local printers made the process easier. She’s been working with Riddle Press - a local family-owned-and-operated printing company - for almost 20 years, which meant when she came to them 6 years ago needing help with an initial design, they were already invested in Elle Crée’s success.

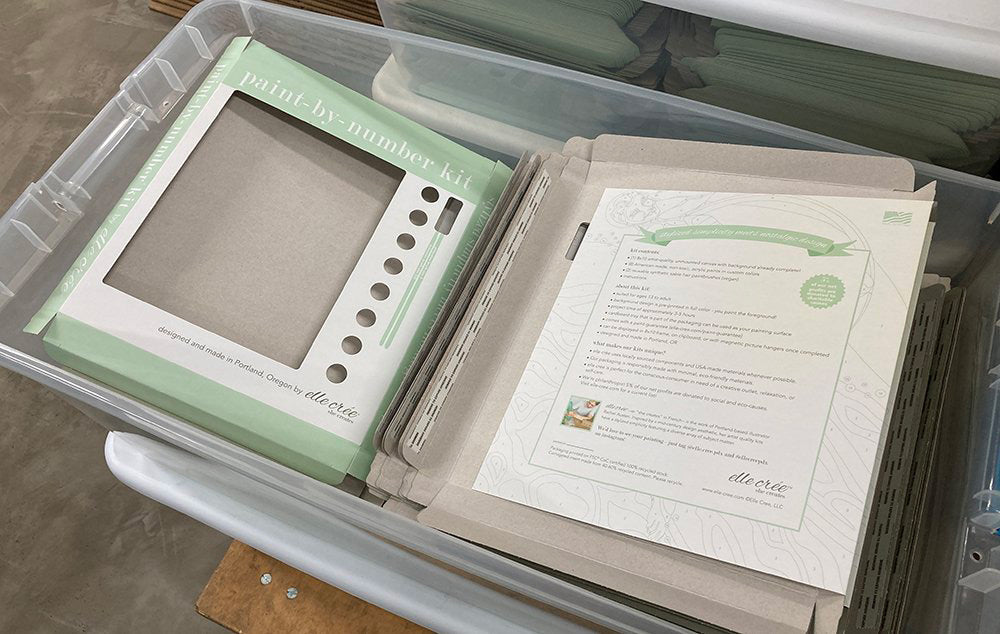

We’ve gone through several packaging iterations, and Riddle Press has been there to help us with each redesign. Rachel has worked with their team to create efficient designs that reduce our footprint, and they’ve helped us source FSC (Forest Stewardship Council) certified paper stock from responsibly managed forests. Our outer packaging is printed on 100% post-consumer recycled stock. Yay!

Knowing how the colors in our kits are going to look is really important to our customers, so we work hard with Riddle Press to make sure our instruction inserts are color accurate. Did you know that all printed colors are composed of 4 different inks - cyan, magenta, yellow, and black (or CMYK for short)? Rachel spends hours out at Riddle working with the pressman to tweak the color balance of those four ingredients for each of our paint colors, so that our instruction sheets give an accurate representation of how your finished painting will look. Many printers would consider that process too time consuming, but Riddle understands how important the color-matching process is to our packaging and accommodates this level of attention to detail.

The internal corrugated cardboard component that holds the paint pots and brushes is produced at a local box manufacturing company. Through lots of trial and error, Rachel worked with their designers to create this structural part of our packaging to fulfill its task of keeping everything in place.

Like our printer, our box manufacturer sources material from local mills. The corrugated cardboard used is made from 40-60% recycled material. Why not 100%? Well, every time paper is recycled the wood fibers that comprise it get shorter, which means that the stock is softer and less sturdy than the original product made of virgin fibers. So, in order to maintain the structure and integrity of the corrugate, it works best to go half and half with recycled materials.

As you can see, the process of creating our packaging is super hands-on, and we wouldn’t have it any other way! We love working with these local printers and manufacturers to bring our sustainably packaged kits to the marketplace and we know you appreciate our conscientious sourcing choices.